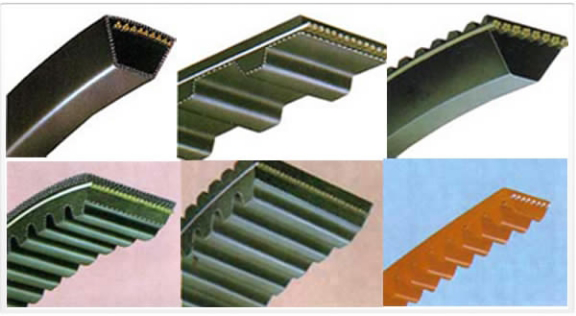

Mitsuboshi is one of the leading manufacturers of power transmission products in the world. Originally based out of Japan, Mitsuboshi today operates out of offices and factories spread over 20 countries. Highest quality products coupled with cutting edge technology, has made Mitsuboshi the preferred belting option for original equipment manufacturers and customers the world over.

Products

- Vee belts

- Wedge Belts

- Classical Timing Belts

- Classical Timing Belts - Double Side

- HTD Timing Belts

- STD (Super Torque timing belts)

- STD (Super Torque timing belts) - Double Side

- Variable Speed Belts

- PU Timing Belts

Infinitive belts creating future infinity

Belts that transmit power. This is the origin of Mitsuboshi belts.

Throughout the Japanese industrial development, Mitsuboshi belts have been continuously running powering industries into the future. We have been expanding our expertise into various areas of today's diverse needs, from daily products manufacturing to industrial machine components and ambitious land and artificial reservoir projects.

Mitsuboshi Belting has achieved numerous milestones. In this day and age, we ask ourselves what is really critical for people living in this era. What must we strive to create now for a better tomorrow. It is with this firm belief that we passionately produce belts for the new age and the good of mankind. Belts embracing infinite possibilities. We want to touch human hearts.

From Kobe, the Mitsuboshi network reaches across Japan and around the world. Mitsuboshi Belting began business in Kobe, Japan, in 1919. Over the years, the business has grown together with its markets, production systems have been continuously improved, and sales and service strengthened. Today the Mitsuboshi Group operates around the world, and looking ahead to the 21st century and beyond, we see the group becoming an important contributor to more affluent lifestyles worldwide.

POWER TRANSMISSION

In 1917, John Gates revolutionized industrial machinery with the world’s first rubber V-Belt, and began the legacy of advanced design that defines The Gates Corporation. In 1945, Gates invented the first toothed timing belt, known as the synchronous belt. In 1979, we created the serpentine belt that changed automotive transmission as we know it. Continuous innovation isn’t just what we do. It’s who we are. Trust the leaders in research, design, material science, and the manufacturing of the best power transmission solutions in the world - only with Gates.

NRB Industrial Bearings Limited is a leading manufacturer of ball and roller bearings for the industrial market. Manufactured at world-class facility in Shendra, Aurangabad, NIBL work with OEMs and end-users to increase uptime while keeping the costs down. With a pan-India sales force, a wide distribution network and Industry engineering support, NRB Industrial is giving its customers the advantages in an increasingly competitive market scenario.

Products

- Deep Groove Ball Bearings

- Spherical Roller Bearings

- Angular Contact Ball Bearings

- Cam Followers

- Bottom Roller Bearings

- Wide Inner Ring Ball Bearings & Housed Units ( Unit & Block Bearings )

- Cylindrical Roller Bearings

- Tapper Roller Bearings

The name JK Fenner has been synonymous with quality & reliability in Mechanical Power Transmission Engineering across the globe for over 150 years offering not only the best of products but also complete solutions. Our range of products viz. s, Pulleys, Couplings, Variable Speed Drives, Clutches & Gear Boxes have become the industry bench-mark over the years being manufactured in state-of-the-art facilities accredited with various Quality Certifications.

Industrial Transmission Drives have been synonymous with quality & reliability in Electro Mechanical Power Transmission Engineering offering the best quality products and complete transmission solutions.

Our range of products viz. Pulleys, Couplings, Gear Boxes, Geared Motors, Vibrator Motors have become the industry bench-mark over the years being manufactured in state-of-the-art facilities accredited with various Quality Certifications.

The Application engineers are well qualified and extensively trained to offer optimum “Drive Solutions” in Industry segments like Material handling equipment, Cement, Coal, Steel, Sugar Mills, Tea Gardens, Food Processing and Dairy Plants, Printing Machinery and other Engineering Industries.

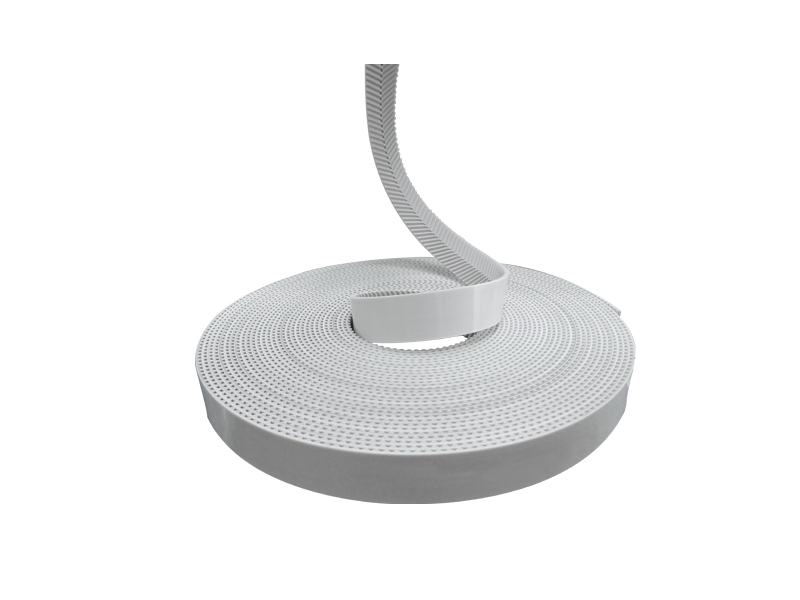

Based in Italy, Megadyne is one of the leading manufacturers of Polyurethane timing belts in the world. Having undertaken intense research in this segment, many technological advances in this field are attributed to Megadyne.

Products

- Polyurathene timing Belts

- Megapower

- Mega Linear Belts

- Mega Flex Belts

- Special PU & Coated Belts

JAPAN FLAT BELTS TANGENTIAL BELTS AND CONVEYOR BELTS.

Products

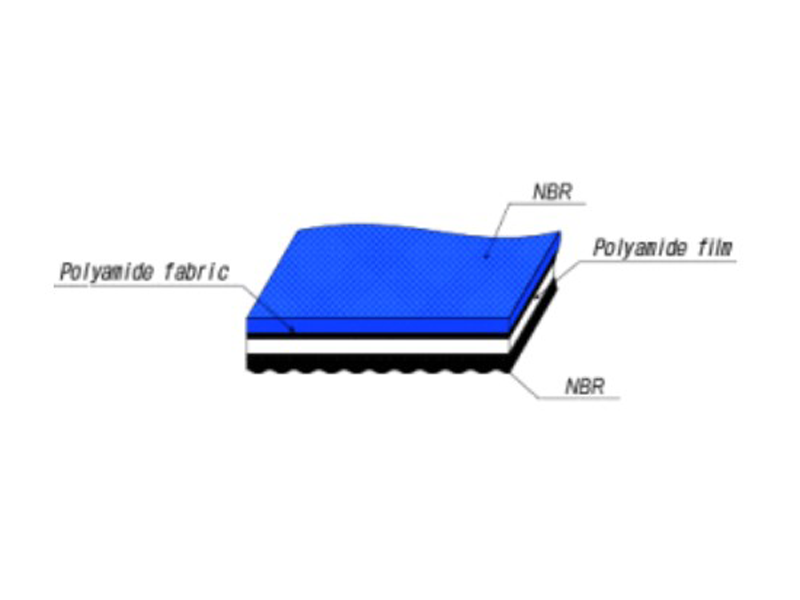

Nitta is a leading manufacturer of a variety of high quality flat belts at their factory in Japan, which have wide applications across industries, as listed below:

- Nitta Poly belts:

L500, LA35, TFL – 65 for general power transmission& tangential belt applications.

MA1500S, TFL12S, TFL155, TFL185, LA2-1800S, TM-18-SHE for tangential belt drivers for TFO (Savio, Voulkmenan, Murata etc.) & Texturizing machines (Alidhra, Himson, Bhagat, Barmag etc.) MB -100S & MB1000GSR & TFL10S for tangential (opening roller & rotor belt) for OPEN END machine such as SCHLAFHORST, REITER etc. - POLYSPRINT belts:

TFL-E, TFL –E, TFE30 for applications with small pulley diameters and tangential belt application on spinning machines such as Zinser. - SE belts:

Special super endless belts for high end applications such as Drum belts (512 X12) in Autocones winding machines. - Spindle Tape & Other:

SG500, KS-250, STC-10, HUS- 500 for spindle drive applications, preparatory machines in textilespinning machines. - Belts for Folder Glues, Carton Making and Printing & Packaging industry are XH500 - 3mm, 4 mm & 6 mm thick.

- Conveyor belt (NLG)

Poly V ® the Belt for All Applications

Poly V ® is a power transmission ribbed belt.

It operates from contact between the ribs of the belt and the grooves of the pulley.

Its one piece structure guarantees an even distribution of tension across the width of the pulley where the belt is on contact.

- These belts eliminate belt matching and permits drive design to meet exact power or space requirements.

- They permit cooler running and high drive efficency.

- These belts excel on small pulleys at high speeds.

| RANGE | PJ | PK | PL | PM |

|---|---|---|---|---|

| PITCH | 2.34MM | 3.56MM | 4.7MM | 9.4MM |

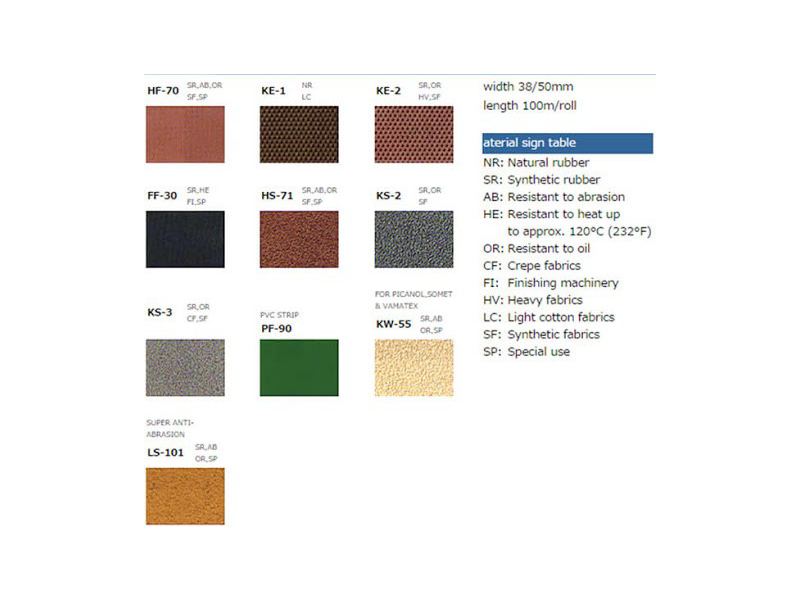

A pioneer in rubber technology since 1943, Kureha has accumulated know how for various kinds of material from NATURAL and SYNTHETIC rubber to TPE (Thermo plastic elastomer) based on rubber processing technologies. Kureha Elastomer Company Ltd. has over 40 years of experience in the textile industry. Their rubber strips (roll coverings) are particularly popular with Japan's major textile machine manufacturers like Tsudakoma, Nissan, Toyoda and Ishikawa who are using Kureha rubber strips as exclusive original equipment parts.

Volta Belting Technology Ltd. has been a world leader in the manufacture of Thermoplastic Elastomer (TPE) belting and profiles for over 50 years.

Volta Belting's homogeneous belts are known for their high material strength, superior dimensional exactitude and stability. The materials are cut- and wear-resistant and impervious to water, oils and other fluids. They are easy to install on-site, with a minimum of contamination to the work area, and, if damaged, can be repaired efficiently by closing tears or replacing sections.

Products

- PU round and Vee belts

SKF is a world renowned name in the field of BEARINGS / BLOCKS / SOCKETS / POWER TRANSMISSION PRODUCTS / OIL SEALS AND VARIOUS ALLIED PRODUCTS. Recognized worldwide for their superior quality and long service life, SKF ball, roller and plain bearings and other all products are the perfect choice for a wide range of applications.

In response to the ever-demanding performance requirements of modern machinery, SKF developed the SKF Explorer performance class of rolling bearings. SKF Explorer bearings reduce environmental impact by enabling downsizing and reducing both lubricant and energy consumption. Just as importantly, SKF Explorer bearings can reduce the need for maintenance and contribute to increased productivity. Skf power transmission products provides perfect support to the bearings and its sound running. We deal in complete range of SKF products.