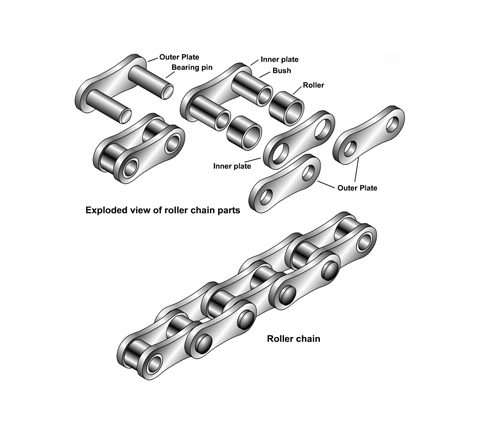

Chains

Reduce maintenance costs with robust quality chains

Mean-time-between-failures (MTBF) is an important measure of reliability, and is critical in power transmission systems. Robust chain drives extend mean-time-between-failures, which reduces maintenance costs.

Some chain systems are of inferior quality, having low wear resistance and little ability to withstand harsh conditions such as temperature variation and shock loading.

Our wide variety of chains include many high-performance variants, and are often specified when other products fail. One of our customers – a foundry in India – found that locally made chains wore out very quickly. Using our roller chains, they cut downtime and maintenance costs by 40%.

All our chains undergo strict quality control from monitoring the raw material used in individual components, to testing the finished products. Chain drive calculators, power rating tables and expertise from our engineers help you to specify a chain correctly.

You can browse and specify products by clicking the ‘Online Catalogue’ button, then choosing a product from the drop-down menu.

Features

- All products conform to ISO, and standards including ANSI, DIN and JIS

- Available in many standard product types

- Chains work from –20 to +150°C (stainless steel chains work up to 400°C)

Benefits

- Raw materials tested against tight specifications

- Processes such as annealing and shot peening further enhance performance

- Calculation tools available

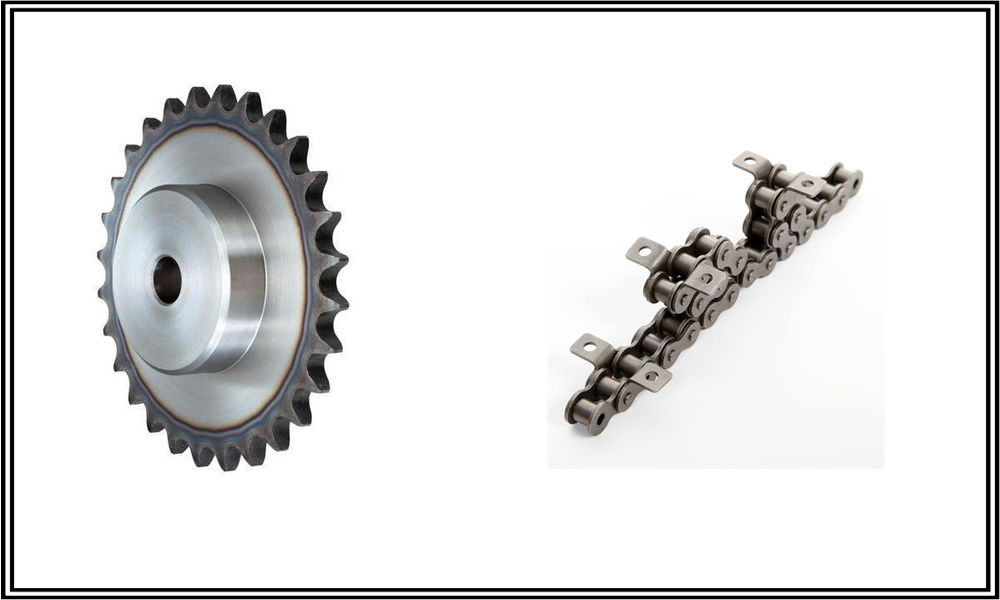

Sprockets

Find the perfect sprocket for your application

Selecting a power transmission component can be challenging, especially when it is a fundamental part like a sprocket.

Products must be available in many sizes, to fit a variety of design envelopes – and avoid the need for customised parts. With our comprehensive range, you will easily find the correct sprocket size for your application.

All our sprockets are made from high-quality steels and can be further adapted for high performance with coatings such as black oxide or zinc plating. Sprockets are available in a variety of configurations, which must be matched accurately to a machine’s design.

Our online catalogue simplifies this selection process and helps you identify quickly the correct product.

Products can be specified either by designation or product type. A designation search brings up a list of all relevant products, such as ‘Metric Duplex, Taper Bushed’ or ‘ANSI Simplex, Pilot Bore’. Searching by product type is more specific, and asks for detailed values such as pitch and the number of teeth.

To start searching for the correct size and type of sprocket, click the Online Catalogue button, then select from the menu.

Features and benefits

- Manufactured according to ISO606 & ASME B29.100 standard

- Available in plate, single hub and double hub configurations

- Made from high-grade steel and carbon steel

- Optional taper bushes simplify installation and removal

- Special products made from grey cast iron HT250 or cast iron 250

- Surface treatment, including black oxide, available on request