V-belt pulleys (also called vee belt sheaves) are devices which transmit power between axles by the use of a v-belt, a mechanical linkage with a trapezoidal cross-section.

Together these devices offer a high-speed power transmission solution that is resistant to slipping and misalignment.

V-belt pulleys are solely used for transmitting power between two parallel axels. The most notable difference between a v-belt pulley and other types of pulleys (round belt, flat, etc.) would be the geometry of the groove or grooves located around the circumference of the pulley; these grooves guide and gain traction on a v-belt. The accompanying video offers a comprehensive overview of some v-belt basics, as well as their advantages and variations.

A v-belt is a unique mechanical linkage with a cross-section that resembles an isosceles trapezoid. The v-belt and its complementing pulley create the most efficient belt drive known (sometimes achieving 98% transmission efficiency). V-belts were developed in the early days of automobile innovation to improve belt reliability and torque transmission from the crankshaft to rotating assemblies. V-belts remain a common type of serpentine belt today.

V-belt transmissions are a notable upgrade from round or flat belt transmissions; v-belts provide excellent traction, speed, and load capabilities, while enjoying an extended service life with simple replacement. Heavy loads actually increase transmission efficiency since they wedge the belt further into the pulley's groove, thereby improving friction. Typically, v-belt drives operate between 1,500 to 6,000 ft/min, with 4,500 ft/min the ideal capacity for standard belts. Some narrow v-belts can operate at speeds of up to 10,000 ft/min, but these pulleys must be dynamically stabilized. V-belt pulleys may be placed in a side-by-side configuration or a single pulley may feature multiple grooves around the circumference in order to accommodate a multiple-belt drive. This type of drive distributes torque across several belts and provides a mechanical redundancy.

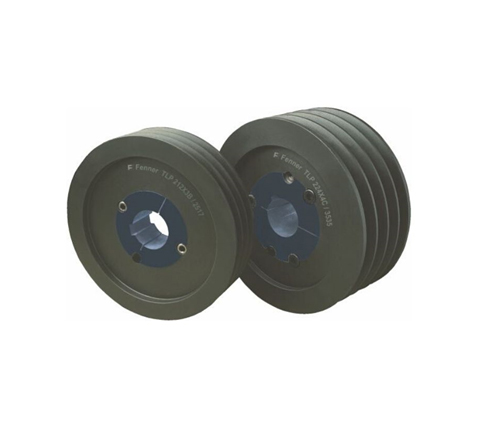

Tapper Lock Pulley

First-ever range of standard metric pulleys to be Made in India.

Dual-duty grooves to perfectly match Classical ‘V’ & Space saver Wedge Belts

With Taper Lock Bushes, changes in diameter and position of pulleys can be easily done

Drives up to 250kW at 1440 RPM

Speed ratio up to 1:7

Over 470 standard sizes to meet a wide range of requirements.

V cool Pulley

Material: SG500/7.

High Tensile Strength & Hardness.

Provided with cooling vents to lower the energy losses and facilitate easy heat dissipation.

Lightweight , Dynamically Balanced and suitable for higher rpm.

Saves power

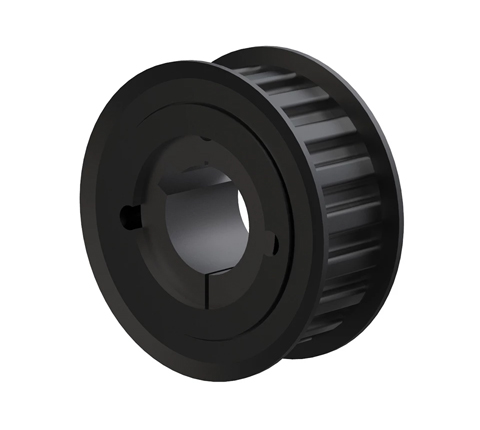

Timing Pulley

Positive Non-Slip Drive.

- Timing Pulleys: ‘L, XL & ‘H, XH PITCH

- HTD Pulleys: ‘5M’, ‘8M’ & ’14M’ PITCH

Positioning accuracy at constant driven speeds.

Compact design & high flexibility.

Reduced belt tension & energy loss.

Optimized tooth design providing optimum.

Reduced operating cost.

Wide range of applications.