These belts are innovative truly endless high performance power transmission belts with termo set resin body and steel traction cord.The high modulus cords used in the belt production allow great length stability and low bearing load.

These belts offer high power transmission capabilities , very high chemical resistance and particularly to oils,greases and gasoline.the application temperature between -30 degree to +100 degree. These belts are available with various kinds of cords like steel cord , aramide cord , Kevlar cords , glass fibre cord etc.

The belts are maintenance free and superior abrasion resistance

| Range | XL | L | H | T2.5 | T5 | T10 | T20 | AT5 | AT10 | AT20 |

|---|---|---|---|---|---|---|---|---|---|---|

| Pitch | 5.08 MM |

9.525 MM |

12.70 MM |

2.5 MM |

5.0 MM |

10.0 MM |

20.0 MM |

5.0 MM |

10.0 MM |

20.0 MM |

Features

Characteristics and Applications:

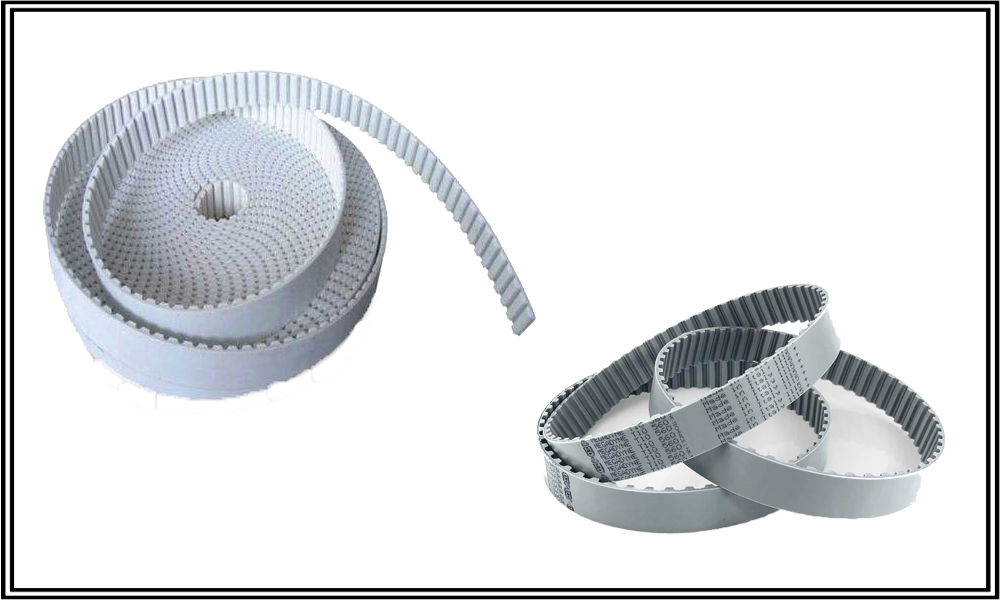

Polyurethanetiming belts are used for high load and resistance applications. The high qualitypolyurethane gives excellent abrasion and shear resistance, combined with a variety of graded steel cords, ensuring high strength and tractive resistance. The result is a timing belt with excellent dimensional stability. Our range of high qualityPolyurethaneTiming belts are manufactured to a tight tolerance range, which assures consistent length and thickness. The combination of these factors results in these belts performing to the highest physical and chemical levels.

PU timing belts are suitable for high power and precision motion control, even at high speeds.

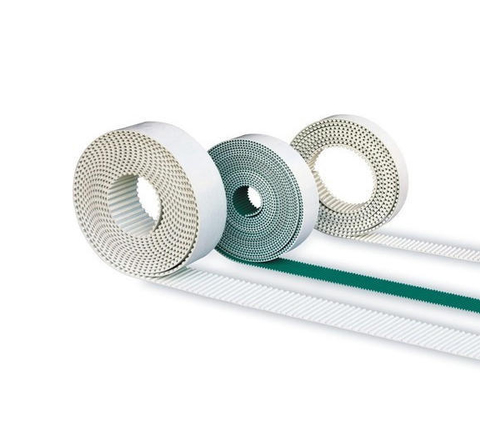

These timing belts come in a wide range of pitches and also in form of open rolls which can be used for a wide variety of applications in various different industries.

These belts have the following features:

Mechanical Features

- Consistent dimensional stability - Low pre-tension

- Low noise

- High abrasion resistance

- Low maintenance

- High flexibility

- Linear speeds up to 80m/sec

For all intermediary sizes or queries please contact our sales department..

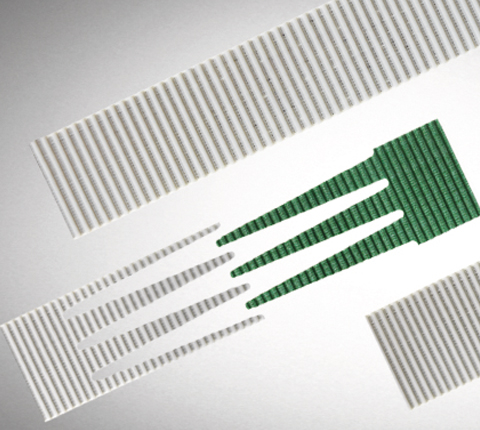

Pu Belts Are Basically Are Moulded( Flex Type ) Or Jointed.

PU FLEX BELTS: These flex belts are manufactured with truly endless high tensile steel tension cords and wear resistant polyurethane body.Having no splice or welding the belts have no week cross section . They are therefore ideal for power transmission application and high load conveting application the unique high tech manufacturing process designed allows the production of every belt length tooth by tooth from the min. of 1500 mm to maxium of 22000 mm.

PU JOINTED BELTS: These jointed belts are made in various non standard sizes from open rolls. They are joined with latest start of art machines so its all layers join perfectly and gives proper life. These kind of belts are very useful for making any special purpose belts.