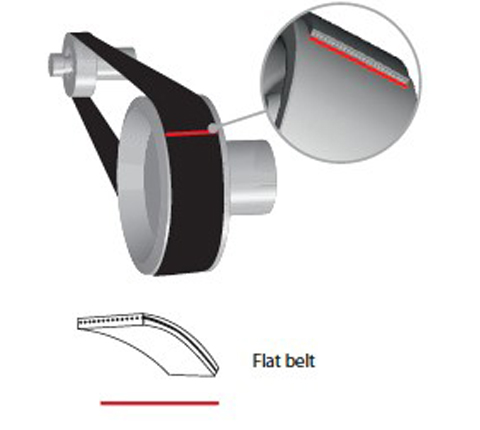

The Poly V is a power transmission belt featuring multiple longitudinal ribs.

It transmits the torque by contact of the belt rib flanks and the pulley grooves.

Its Monobloc Design Guarantees:

- Compactness

- High power transmission

- Operating cost

COMPACTNESS:

The Poly V has been designed with a larger contact surface area than V belts or flat belts.

The Poly V has multiple application benefits:

- Improved Transmission Ratio: is possible (Poly V 1 : 60 vs V belt 1 : 20). Does away with the need for stepped pulleys.

- Reduced Diameters: (diameters up to 9mm with the H profil compared to 50mm with V belts).

- Reduced Belt: width for a given geometry and the same power transfer

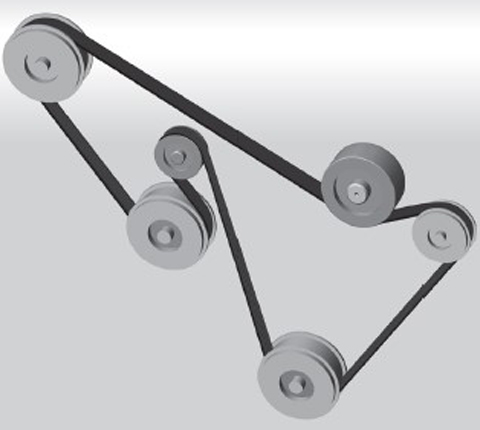

Moreover, the Poly V can operate in flexion and counter flexion with the following benefits:

- A single belt can drive several accessories: serpentine belt installation.

- Driving accessories from the back of the belt.

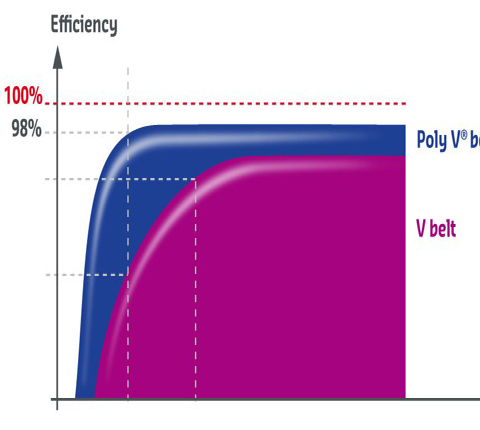

HIGH OUTPUT:

Smaller Carbon Footprint:

Iso-tension and iso-geometry technical tests show that the Poly V can achieve an output several percent higher: over 98%, which can reduce energy consumption and sometime even engine size.

REDUCED COSTS:

Smaller Carbon Footprint:

Iso-tension and iso-geometry technical tests show that the Poly V can achieve an output several percent higher: over 98%, which can reduce energy consumption and sometime even engine size.

Benefits:

- Reduced diameter and pulley width.

- Reduced belt length.

- No need for inertia flywheels in some cases.

- Machining of pulleys is facilitated: the Poly V can be used on smooth pulleys (receivers).

Maintenance:

- Rapid set up (1 Poly V can replace up to 15 V belts).

- No need for matching.

- Increased lifespan

Operating:

- Reduced consumption due to high output.