Polyflex® Jb™ Or Polymax Belts

Polyflex® JB™ is synonymous with high power density in small spaces. Developed by Gates and produced to patented manufacturing processes, these belts provide more load-carrying capacity at higher speeds to small multiple V-belt precision drives. This results in significant cost savings and improved design freedom. Polyflex® JB™ belts are recommended for use on bench type milling machines, lathe drives, woodworking and metalworking machine spindle drives, computer peripheral equipment, small blowers, etc. They are available in 3M-JB, 5M-JB, 7M-JB and 11M-JB sections.

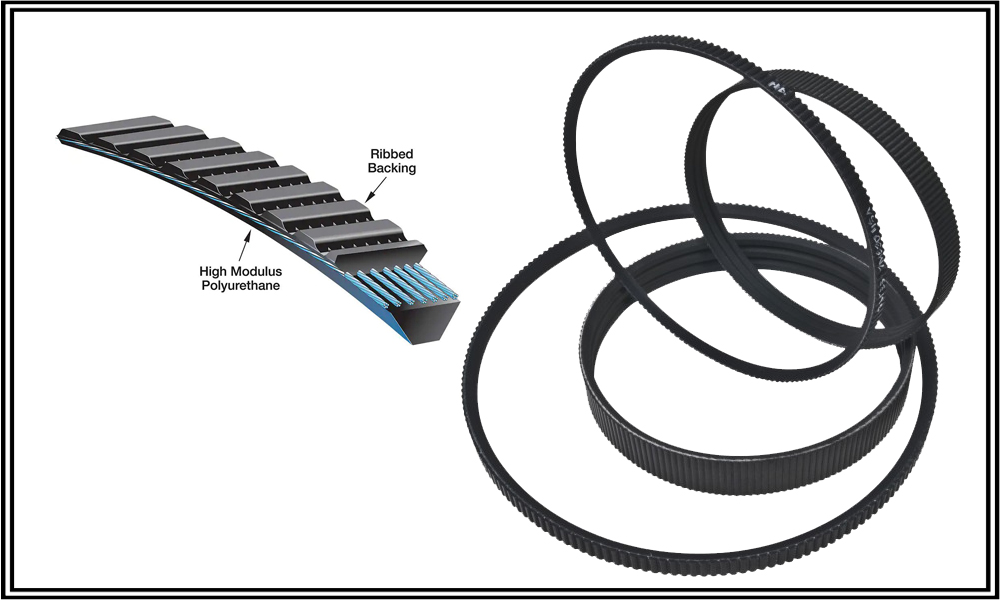

- High modulus polyurethane compound with a high friction coefficient.

- The polyurethane compound resists fatigue, wear and ozone

- Temperature Range: -54°C to +85°C (-65°F to +185°F).

| Range | 3M | 5M | 7M | 11M |

|---|---|---|---|---|

| Cross Section | 3 * 2 MM | 5 * 3 MM | 7* 5 MM | 11 * 7 MM |

Features And Benefits

- Excellent adhesion of tensile cords and polyurethane compound leads to high fatigue resistance and long belt life.

- Small cross-section meets special application needs such as high shaft speeds, small drive package size and smooth running requirements.

- The 60° angle provides more undercord support to the tensile section and distributes the load more evenly.

- Ribs relieve bending stress on small pulleys and provide lateral rigidity.

- Long belt life on small pulleys and compact drives.

- The precise casting method eliminates overlaps and layers.

- High performance and smooth running for precision applications.

- Avoids vibrations when subjected to shock loads.

- Joined Belt construction improves stability.

- Greater shaft speeds, up to 30,000 rpm.

- Cost savings and design freedom.